Nidec Graessner Austria Industry expertise

Gear solutions from Nidec Graessner Austria can be used in almost all areas. Our customised solutions according to your specifications ensure an even more specific application.

Robotics and automation Man and machine hand in hand.

We are the robots - what made the German band Kraftwerk a hit in the 1970s is more true today than ever. From an economic point of view, robots are indispensable for more and more tasks in a wide range of industries. For an optimal interaction between man and machine, in order to optimally handle specific tasks.

As a competent partner for demanding customers, you can count on our many years of experience in robotics and automation. During the development of the drive train, special attention is paid to availability and load capacity. High-precision gearing solutions inside the gearbox as well as complete system solutions are our speciality.

In addition, we offer a complete standard range of dynamic angular gearboxes, which are characterised by the fact that they are ideally suited for a wide range of automation solutions thanks to minimal adaptations. Highest availability and reliability coupled with power density and optimum energy efficiency are the hallmarks of all our products.

Below you will find the optimal gearboxes for your industry sector:

Flexwave

VRT

Picture Source: Kuka Roboter GmbH

Machine Tools Always on the move for you

When used in the machine tool sector, everything revolves around maximum duty cycle at highest speeds. And we have very special solutions for these special requirements.

Precise, high-torque and fast - the feed drives in the machine tools are designed, among other things, with our bevel-helical gear units also in master-slave combination including rack and pinion. This ensures high rigidity and high dynamics.

The auxiliary drives of the machine tools are also as varied as they are demanding: During sawing, drilling, milling, planing, pressing, grinding, machining, finishing - to name just a few processes - efficient clamping, swivelling and centring is required. Our experienced engineers will find an optimum solution here. A large number of renowned customer references also speak for this. By the way: Our engineers are also happy to develop special solutions for machine tool construction in cooperation with customers or according to specifications. Because we love a challenge.

Below you will find the optimal gearboxes for your industry sector:

VRS

PowerGear

Picture Source: CHIRON Werke GmbH & Co. KG

Drive Technology Our drive: Your success

Your competitiveness drives us. In concrete terms, this means: We develop highly efficient bevel gear units as pre-stage or even post-stage in combination with switched planetary gear units or other precision gear units. With highest precision, small installation space and highest torques.

Our customers can rely on more than 60 years of experience and at the same time on a pronounced willingness to innovate in drive technology. Nidec Graessner Austria gears prove this day after day in almost all industrial sectors.

Last but not least, the extremely high reliability and long service life of our drive solutions enable end customers to produce safely and predictably. Our products and our services thus reliably secure the production of the industrial plants of our clients or their customers worldwide.

Our range of services is almost limitless: We offer the complete engineering of the drive train as well as the production including service. Among other things, we offer gearing solutions, angular gears, spur gears and planetary gears for a wide range of applications. In developing customer-specific solutions, we look beyond the horizon - by taking a holistic approach to the task at hand.

Below you will find the optimal gearboxes for your industry sector:

VRS

KS TwinGear

Picture Source: TAKRAF GmbH

Packaging machines for the food sector Cheers - our gears are pure pleasure

Almost nowhere else are the demands for purity greater than in the food industry. The same applies to the availability of filling and packaging machines - because downtime can be expensive.

Our gearboxes, available in stainless steel or coated versions, meet these high hygiene requirements. They enable optimum cleaning with minimum dirt adhesion. Food-safe lubricating oils are a matter of course. Our drive here is: to develop particularly energy-efficient drives and to generate solutions that allow machine manufacturers to generate real competitive advantages for their customers in the food industry.

Below you will find the optimal gearboxes for your industry sector:

VRL

EvoGear

Picture source: ILLIG mechanical engineering GmbH & Co. KG

Measuring and testing technology Trust is good - control is better

Faster and faster time-to-market processes characterise the corporate landscape today. Due to the ever shorter cycle times of new products, highly efficient test benches are of particular importance. We have experience with this - because for decades we have been supporting our customers with special test bench gearboxes.

Our highly dynamic labyrinth gearboxes meet all requirements for efficiency and smooth running.

For example, we offer the automotive industry with its modern production processes and a high degree of automation efficient solutions for their test benches.

Below you will find the optimal gearboxes for your industry sector:

PowerGear

VRS

Picture Source: AVL Schrick

Medical Technology The technology behind modern medical technology

Today, state-of-the-art drive technology and innovative medical technology solutions often go hand in hand. Thus our mechanical drive solutions are used in many areas of medical technology.

Small angular gears, such as miniature gears in stainless steel with a planetary gear as a preliminary stage, are often used for therapeutic equipment, among other things. Here, the patient can be offered permanent assistance with efficient accumulators and our drive solution. For example, with intelligent prostheses and many other solutions in the e-health sector. It is not for nothing that our customers here are usually high-tech companies and innovation leaders.

Technical competence in combination with a high safety rate of our systems has top priority. Our numerous calculation and design programmes guarantee further support during development and subsequent pilot production. Our knowledge in the field of medical technology, which is as sound as it is broad, is the basis for finding solutions quickly. It is therefore no wonder that our medical technology solutions move customers and patients both at home and abroad.

Below you will find the optimal gearboxes for your industry sector:

Flexwave

PowerGear Mini

Picture Source: ReWalk Robotics, Ltd.

E-Motives The whole world on the move

E-Motive moves the world. And we are also ahead in this area - our many years of experience in electric mobility are setting international standards. We have been a competent development partner for our customers in the E-Motive sector for several years. We are your contact for the development of e-bikes, lawnmowers, sport boats or parking aids - to name just a few products. Our know-how across the entire drive train enables energy-efficient systems with a long service life.

Our drive solutions convince through high power density, low weight and outstanding efficiency.

Our range of services: We offer the complete technical design for the e-motive sector - also for hybrid and electric vehicles. Our in-house service package with experienced engineers completes our range of services.

Below you will find the optimal gearboxes for your industry sector:

DesignGear

VRL

Machine and plant construction Our claim is nothing less than setting standards

For over 60 years we have been the competent partner for companies in the field of mechanical and plant engineering. The requirement is strictly speaking always the same: the most compact size possible with simultaneous transmission of the highest possible torques. And we translate this requirement individually for each project - always with the aim of setting standards.

Whether it's angular gearheads or other mechanical gearheads, we always aim to be the number 1 in our field.

We also manufacture high-precision spur and bevel gear sets, planetary gears as well as dynamic and robust bevel gears for a wide range of applications. Especially in the development of customer-specific solutions, our internal processes, such as our efficient workflow management, make us unique. And we are pleased that our numerous customers see it the same way - and confirm this to us through long-standing customer relationships.

Below you will find the optimal gearboxes for your industry sector:

VRS

DynaGear

Picture Source: Cantec GmbH & Co. KG

Nidec Guided Gear [NGG] Drives for industrial self-propelled vehicles

Standardised transmission systems for self-propelled transport vehicles.

- Highly standardised transmissions, therefore quickly available

- Cost-optimised solution suitable for all applications

- Modular motor attachment for free motor selection

- 2 designs, coaxial and angled

- 4 wheel sizes with resistant, low-noise running surface

- High efficiency of the components

- Maximum reliability

- High dynamic load capacities up to 1200kg

- High travel speeds up to 2m/s

- A variety of transmission ratios for optimum drive design

- Protection class IP65

- High efficiency >95

Learn more about our NGG.

Food industry Heroes of food production

Our planetary foodgrade gear series have expanded their wash down options to include additional features in a wider breadth of series and frame sizes. These features can handle wipe-down and light-to-medium wash down requirements in different areas of the manufacturing floor, from primary processing to secondary packaging. Common configurations are stocked and assembled in Europe for high flexibility and quick turnaround at the most cost-effective price point in the market.

Our modular adapter system allows for simple, streamlined mounting to any standard servo motor. For axes with space constraints, we offer several of these features in a right-angle configuration, utilizing planetary, worm, hypoid or bevel gearing technology.

Learn more about our NFG.

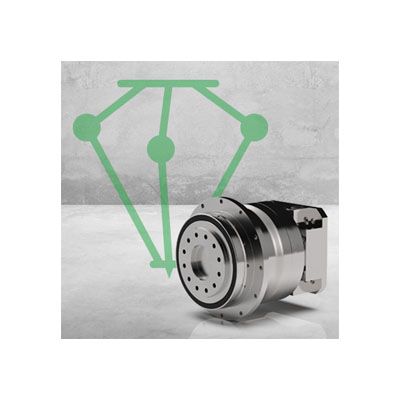

Packaging industry, medical and pharmaceutical industry, electronics sector Gear system for sorting and packaging wonders

Our NDG series are gear systems for High-Speed Pick & Place tasks. It has been adapted to the special tasks of delta robots and is used for highly dynamic sorting, placing and selecting.

Learn more about our NDG.